Drilled Concrete Cores

QCS 2010 (BS EN 12504-1:2009 & BS EN 13791:2007), This method statement specifies the procedure for taking cores from hardened concrete, their examination, preparation for testing, and determination and evaluation of compressive strength.

TEST METHOD

BSEN 12504-1, 2009 “Testing in Concrete Structure; Cored Specimen-Taking, Examining and Testing in Compression”.SIZE, NUMBER OF CORES, AND LOCATION

BSEN 12504-1, 2009 preferred a diameter of 100mm for 25mm aggregate size or smaller, it is generally accepted that the core diameter/maximum aggregate ratio should be above 3 in order to reduce test variability to an acceptable level, while the minimum number of cores to be obtained, tested and then to

Sampling location, To avoid cutting reinforcement, we will scan it with a cover meter machine before any coring process.

DRILLING OF CORES

Core drilling is carried out by an experienced operator using water-cooled, diamond-impregnated coring barrels driven by electric equipment. Care should be taken during coring using the cover meter to avoid, as much as possible, cutting off steel bars.The ring is usually bolted firmly to the concrete and care is taken over the coring rate to ensure a parallel core sample is cut perpendicular to the surface.

The sample is severed by inserting and tapping a cold chisel down the annulus cut by the barrel to cause a break-off at the bottom of the drilled length.

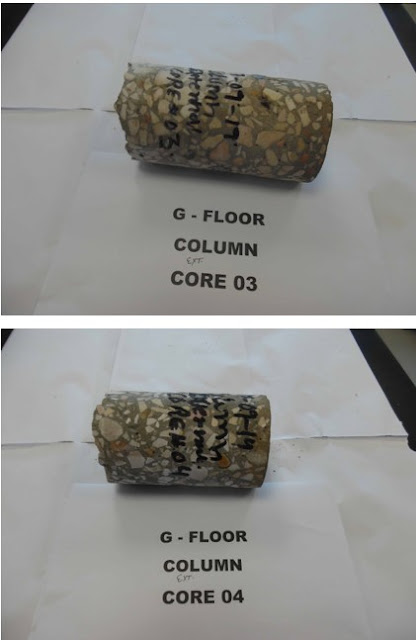

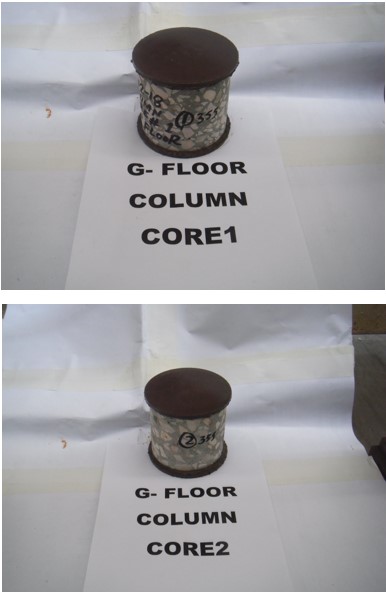

Once the samples have been cut they should be marked with a reference number, orientation mark, and location from within the structure and wrapped in polythene.

Core drilling shall be done in the presence of the engineering representative.

VISUAL EXAMINATION AND MEASUREMENT

The cores are to be visually examined to identify any abnormalities, presence of voids, honeycombing, compaction, cracks and segregation, coarse aggregate type, and particle shape.Core diameter shall be measured to within ± 1% from pairs of measurements taken at right angles, at the half and quarter points of the core.

Core length, the maximum and minimum lengths shall be measured to ± 1% as received and the length after completion of the end preparation.

CORE PREPARATION AND CORE CONDITIONING

The high-speed grinding using diamond-faced is the means used for the end preparation of test cores.The preferred length diameter /ratio is.

1. 2.0 If the strength result is to be compared to cylinder strength.

2. 1.0 If the strength result is to be compared to cube strength.

The test cores are to be exposed to a laboratory atmosphere for at least 3 days prior to testing except required to be tested at saturated condition cores to be soaked in water at 20±2 0C for at least 48 hours.

The test cores are to be capped with an approved capping material. The Engineer/Consultant shall approve the type of capping material to be used especially for high-strength concrete since mortar capping (by calcium aluminate cement mortar) and sulfur capping which is the commonly used capping material is restricted up to approximately 50 MPa only as per BS EN 12390-3. The other method of end adjustments which is grinding and sandboxing is not available in ACES. For high-strength concrete (80 MPa), ACES suggests the following procedure subject to the Engineer/Consultant’s approval.

Rubber Capping (as per ASTM C1231) – applicable for expected strength over 48 MPa.

High Strength Grout (Fosroc Lokfix) (non-standard) – grout cube compressive strength reaches up to more than 70 MPa after 4 hrs from casting. (See attached technical data sheet).

CORE TESTING

Compression testing is to be carried out in accordance with BS EN 12390-3 using a compression machine conforming to BS EN 12390-4.The compressive strength is obtained by dividing the maximum load by the average cross-sectional area and expressing the result to the nearest 0.1 MPa.

EVALUATION OF TEST RESULTS

According toThe strength class is obtained from Table No.1 below using the estimated in-situ characteristic strength.

Table 1 – Minimum characteristic in-situ compressive strength for the EN 206-1 compressive strength classes.

|

Compressive

strength class according to EN

206-1 |

Ratio of in-situ characteristic strength to

characteristic strength of standard specimens |

Minimum

characteristic in-situ strength N/mm2 |

|

|

Fck,

is, cyl |

Fck,

is, cube |

||

|

C 8/10 |

0.85 |

7 |

9 |

|

C 12/15 |

0.85 |

10 |

13 |

|

C 16/20 |

0.85 |

14 |

17 |

|

C 20/25 |

0.85 |

17 |

21 |

|

C 25/30 |

0.85 |

21 |

26 |

|

C 30/37 |

0.85 |

26 |

31 |

|

C 35/45 |

0.85 |

30 |

38 |

|

C 40/50 |

0.85 |

34 |

43 |

|

C 45/55 |

0.85 |

38 |

47 |

|

C 50/60 |

0.85 |

43 |

51 |

|

C 55/67 |

0.85 |

47 |

57 |

|

C 60/75 |

0.85 |

51 |

64 |

|

C 70/85 |

0.85 |

60 |

72 |

|

C 80/95 |

0.85 |

68 |

81 |

|

C 90/105 |

0.85 |

77 |

89 |

|

C 100/115 |

0.85 |

85 |

98 |

|

NOTE

1 – The in-situ compressive strength may be less than that measured on

standard test specimens taken from the same batch of concrete. NOTE

2 – The Ratio 0.85 is part of γc

in EN 1992-1-1:2004. |

|||

REPORTING

The report will be submitted to the client after the completion of field works and laboratory testing. This report will contain.

Project details including date and location of testing. Concrete design details. Visual inspection. Core compressive strength. Estimated in-situ characteristic strength. The report will include an analysis of test results and a conclusion according to QCS 2014.