1. Building Description

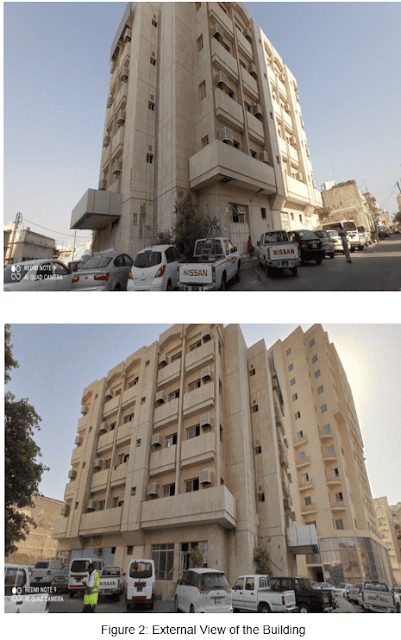

The building

under study is located in ------- at the junction of ---- street with ------

street.

The building

consists of the ground floor and four typical floors. The building is abandoned.

The

structure is made of conventional concrete slabs supported by beams that

transfer the loads to the columns, and the latter transfer the loads to the

strata through footings. The building is enveloped with stone. Figure 1 and

figure 2 illustrate the building from different angles

2. Visual

inspection

During

the physical observation, all floor levels were inspected, considerable

areas were exposed and checked, and a general assessment was conducted.

Investigation for various signs of deterioration was conducted, such as cracks'

patterns, spalling and delamination of concrete, honeycombs, discoloration,

etc. Also, a check for excessive deflection and distress, such as flexural and

shear cracks, was carried out.

The physical observations made during the inspection are summarized below, and figures from 3 to 9 present part of the visual observation.

1.

The structure of the building is moderately

deteriorated

2.

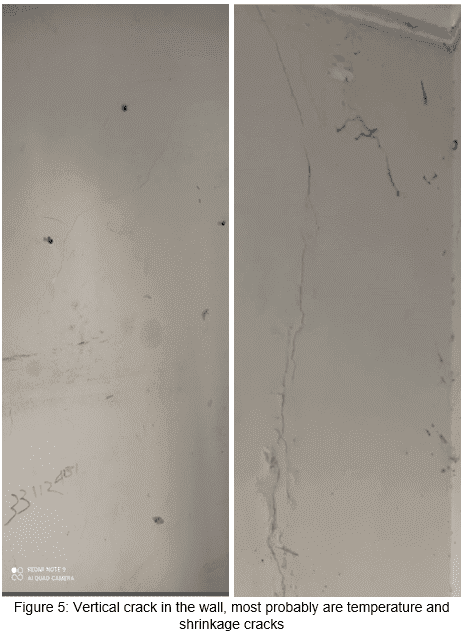

Various temperature and shrinkage cracks were

observed all over the building.

3.

Corrosion cracks were observed. Also, a trail

of corrosion was noticed.

4.

Concrete cover spalling and exposure of

reinforcement were observed in some places

5.

A lot of exposed reinforcement bars have

experienced a size reduction due to corrosion.

6.

Concrete delamination and paint peeling were

observed all over the building.

7.

Vertical cracks between concrete columns and

blockwork were observed in various places.

8.

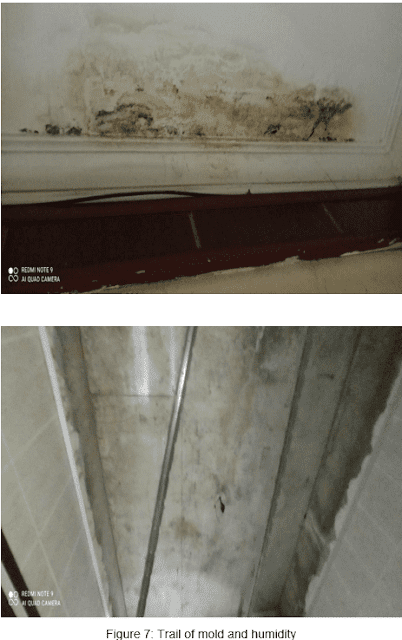

Signs of water leakage were observed in many

places

9.

Trails of humidity and mold due to humidity and

water leakage were noticed.

3. Conducted

Tests

Tests, mainly,

were conducted on the columns since they are the critical structural element in

the building. The following tests were conducted:

1.

Carry out ultrasonic Pulse velocity test as per

EN 12504-4:2004.

2.

Obtain concrete cores from different locations

of the building to assess the physical and mechanical properties of the

existing concrete, according to EN 12504-1:2009.

3.

Measure the carbonation depth of concrete

elements by using the phenolphthalein indicator according to BS 1881-201:1986 and

BS EN 14630.

4.

Extract reinforcement steel sample for a

tensile test following ASTM A370 or ISO 15630-1.

4. Tests

Results

The

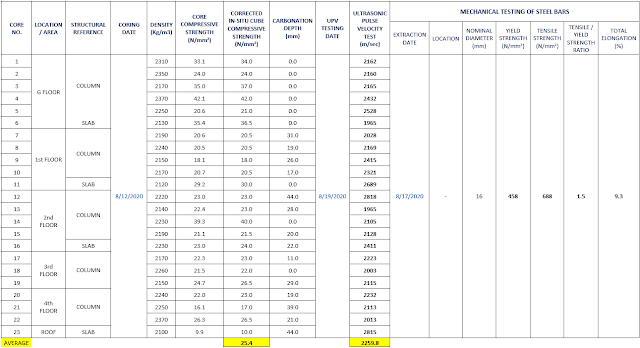

following shows the results of the tests conducted. Table 1 summarizes the

conducted tests' results.

4.1

Ultrasonic test

The ultrasonic test was conducted on

several concrete elements to examine the quality of the concrete in general.

Nineteen columns and four slabs were tested. The results values were varying

between 1965 m/s and 2818 m/s, which means that concrete condition varies

between very poor to poor in condition.

4.2

Compressive strength

test

Twenty-three

concrete cores were extracted, thirteen cores from the columns, and three cores

from the slabs.

Core compressive strength test results vary

between 17 MPa and 42 MPa for columns. As for the slab, on average, the

compressive strength was 25 MPa.

4.3

Carbonation Test

Carbonation was

found in 60% of the tested samples. Carbonation's depth varies between 11mm and

44mm.

4.4

Tensile Test

One specimen was extracted from a column to know the

yield strength of the reinforcement steel used in the structural elements. The

yield strength of the deformed bar was found to be 458 MPa

5. Discussion

of the Visual Inspection and the Tests Results

From the physical investigation conducted, the

tests' results obtained, and the experience with similar buildings, most of the

observed cracks are the expected output due to the bad quality of work, lack of

regular and preventive maintenance, and the effect of variation in temperature

and humidity.

By applying

standard deviation to the Ultrasound tests' results, the average ultrasound velocity

was 2200 m/s, which means the quality of concrete is poor in general. This conclusion was confirmed by the

compressive test results obtained, where the average concrete strength was 22.9

MPa.

Some of the tested columns had shown low

strength values, e.g., 17 MPa. The low compressive strength of the concrete

elements combined with the effect of the cracks in these elements could

adversely affect the strength of these elements. It may lead to the redistribution of the stresses within the building.

About 60% of samples have carbonation,

i.e., the alkalinity of the concrete is decreasing, and protection against

corrosion had gone.

Vertical cracks between the concrete

columns and the blockwork walls are due to temperature shrinkage.

Horizontal cracks between the tiles

finishing layer and the slab are due to temperature variation.

Although the building

is not old, the bad quality control of the work during the construction period

had promoted the corrosion to initiate at an early stage and propagate.

6.

Conclusion

From

the preceding observation and tests' results, the structural condition is

considered poor. From the various inspected locations, and the carbonation in

the concrete and humidity trails, one

can assert that corrosion of the reinforcement steel has been propagating in

many places in the building, and the deterioration is increasing, and spalling

and delamination of the concrete cover will occur in other places. The

structural condition could be considered moderate, and around 20% to 30% of the

structural elements in the building require rehabilitation and strengthening.

The above conclusion was based on the

observed defects during the inspection period, and tests results conducted at

various selected points that could not reveal the condition of not tested

element. Also, to precisely understand the condition and behavior of the

building, the construction drawings should be studied in conjunction with

observation and tests results.