STRUCTURAL INVESTIGATION

This general report presents the overall structural condition of the existing buildings in ----------- and the geotechnical nature of the area. Also, to facilitate locating each building in the zone and its related specified factual reports.Each building's report presents the structural condition assessment based on the conducted visual inspection and tests.

The structural evaluation was conducted per ACI 201.1, ACI 364.1, 224.1, 437, and ASTM C823

1. INTRODUCTION

1.1.

Purpose of the Study

The purpose of this study is to determine the structural

conditions of the buildings and conclude the extent of maintenance required to

rehabilitate each building.1.2. Scope of Work

The scope of work consists of the following,Collect general information about the site, the structure particulars, and environmental data.

Conduct a visual inspection to explore the structural system of each building, to point out the structural deterioration and distresses in each building, and to document the observations by photos.

Carry out ultrasonic Pulse velocity test to evaluate concrete conditions.

Extract concrete cores from different locations, to assess the physical and mechanical properties of the existing concrete according to EN 12504-1:2009.

Measure the carbonation depth of concrete elements by using the phenolphthalein indicator according to BS 1881-201:1986 and BS EN 14630.

Extract steel reinforcement samples for the tensile test following ASTM A370 or ISO 15630-1

Conduct a geotechnical investigation of the area to assess the condition of the strata and collect basic geotechnical data about the area.

Produce a geotechnical report about the area.

Produce a factual structural evaluation report for each existing building.

2. General Description and Available Records and Data

This zone, ---------- is one of the oldest quarters in ------- city, it is part of the old -----. This area is registered under one PIN ------- and is owned by the ------------. The majority of the buildings are old. Based on the observation and general conversation with tenants, these buildings were built during the 70s and 80s eras.Buildings in this zone range from one-level buildings to ten-story buildings, which are used as commercial or residential. The structure of the buildings varies between a conventional concrete building made of reinforced concrete and blockwork and buildings made of blocks and covered with corrugated sheets.

No drawings or maintenance records were available for the buildings in this zone. The only collected data were collected from the occupants of this area.

3. FIELD EXPLORATION AND TESTS

3.1 Visual Inspection

A thorough visual inspection had been carried out on all existing buildings to locate all obvious distress, and deterioration, and to document the extent of the damage to the buildings and its severity that could impair their service or safety.The visual inspection had been accompanied by photographs, as appropriate, to document the buildings' condition. Cracks, spalling, corrosion of reinforcing steel, etc., were identified as per ACI 201.1R as follows:

a) Cracks were located, recorded, and identified as structural or non-structural.

b) Spalling, scaling, honeycombing, efflorescence, and other surface defects were recorded.

c) Corrosion of reinforcing bars, including the extent of the lost cross-section, was recorded.

d) Deformations, where applicable, were investigated.

e) Signs of foundation settlement and related distress were investigated.

f) Water leakage, ponding areas, areas of poor drainage, or other indications of water problems were noted

g) Evidence of aggressive chemical deterioration such as sulfate attack and acid attack were explored.

In general, the visual inspection included the assessment of three basic conditions:

visible damage, visible deviations and deformations, and foundation settlement. It is worth mentioning that it is difficult to quantify the visible damage since it depends on subjective criteria. However, visible damages to buildings were assessed based on the experience with many similar cases.

Visible deviations and deformations: Unintended visible deviations of members from the vertical or horizontal was investigated and recorded, where observed. Comparisons with adjacent structures or members guided the Appraisal of relative movement. Also, deviations from the vertical or horizontal more than about L/250 were considered.

Foundation settlement: The movements, tilt, and separations of structural elements and cracks that result from differential settlements were investigated. A field investigation was conducted to explore the condition of the strata. Also, note any changes in the water table or signs of erosion.

Where signs of differential settlement were present, a more detailed geotechnical investigation to assess the impact of the observed conditions fully had been conducted.

Data in this report are provided to facilitate a quick overview of the inspection results.

The following are the physical observations made during the inspection:

1. Temperature and shrinkage cracks and defects were observed in many buildings, especially at the connection of the concrete blocks with the concrete columns.

2. Corrosion cracks were observed in many buildings.

3. Delamination of concrete covers due to reinforcement bars corrosion was investigated.

4. Spalling and exposure of reinforcement were observed in many buildings.

5. Concrete discoloration and paint peeling were observed in many buildings.

6. Efflorescence, which is a deposit of salt due to the penetration of water through the cracks and the isolation joints, was investigated.

7. Concrete patching and repaired defects were noticed in many buildings.

8. Reinforcement bar is corroded, and the bar diameter has reduced in many places.

The visual inspection had shown that most of the buildings in this area undergo severe deterioration. This deterioration is due to the spalling of the concrete cover due to steel corrosion, joint spalling due to the damage of the expansion joints insulation, delamination, peeling, scaling of concrete due to weather effects, and water leakage due to failure of waterproof systems and lack of maintenance.

3.2 Concrete Core Drilling

Cores extracted using coring drills, carefully examined, prepared by grinding, capped, and tested for compression strength as per BS EN 12390-3: 2009 Annex A standards and procedures.Care was taken during coring to avoid, as much as possible, cutting off steel bars and causing any damage to the structural elements and cores.

Individual building reports present the visual inspection of the concrete cores.

3.3 Carbonation Depth Test

The carbonation test was carried out to determine the depth of concrete affected due to the combined attack of atmospheric carbon dioxide and moisture and causing a reduction in the level of alkalinity of concrete. The carbonation of concrete also lowers the number of chloride ions needed to promote corrosion and reduces the protection of steel against corrosion.The indicator used is a solution of phenolphthalein in diluted ethyl alcohol, which changes from colorless to purple-pink as the pH value rises above 10. Consequently, the outer, carbonated layer of concrete remains its natural color while non-carbonated concrete is stained pink. This test was conducted in accordance with BS EN 14630:2006 and BS 1881-201:1986.

The test results are presented in the buildings' reports.

The depth of carbonation of concrete was measured on three freshly drilled concrete cores by applying a chemical indicator. The test results of the carbonation for the tested locations are presented in the buildings' reports.

3.4 Extracting of Embedded Reinforcement Steel Bars

Steel reinforcement samples were extracted from different buildings to be tested as per BS 4449, to check the mechanical properties of the reinforcement steel.3.5 Ultrasonic Pulse Velocity Test Results

Ultrasonic pulse velocity test was conducted using direct and in-direct measurements for the inspected elements with a path length in cm. The results of UPV readings for the tested elements are presented in the buildings' reports.The quality of the concrete may be considered Excellent, Good, Questionable, Poor, and Very Poor if the ultrasonic pulse velocity is 4500m/s, between 3500-4500m/s, between 3000-3500m/s, between 2000-3000m/s, and <2000m/s respectively.

4. LABORATORY TESTS

4.1 Concrete Properties & Strength

Visual Examination of Concrete CoresThe extracted cores were visually examined before and after preparation and testing. The results of the visual examination are presented in the buildings' reports.

Compressive strength tests were carried out according to EN 12504-1:2009. The results of the physical and mechanical properties of the cores are presented in Tables No. 2 and 3, respectively.

Physical & Mechanical Properties of Cores

4.2 Chloride Content Test

Dust samples were taken from the remaining tested concrete core samples. The dust samples were treated for chemical analysis in accordance with BS 1881: Part 124:2015The results of chloride content, cement content, sulfate content, type of cement, and alkali content are presented in the buildings' reports.

4.3

Ultrasonic

Pulse Velocity Test

Ultrasonic pulse velocity test was conducted using direct and in-direct measurements for the inspected elements with a path length in cm. The results of UPV readings for the tested elements are presented in the buildings' reports.

4.4 Tensile Test Results

The steel bar extracted for the tensile test was obtained from one location of each building.Interpretation of test results of tensile and yield strength and elongation as per BS EN ISO 15630-1:2010 (E); BS EN ISO 6892-1:2016 and Characteristic Tensile Properties are presented in the buildings' reports.

5. Conclusions and recommendations

After complaining about all observations and test results and studying them in an analytical way to determine the cause and rate of progression of existing deterioration or distress and to determine the degree of repair required. A six-point assessment classification is presented as follows:a) Unsafe, i.e. above 80% of the structural elements in the building are prone to failure and require thorough structural renovation and robusting.

b) Potentially hazardous, i.e. 60 to 80% of the structural elements in the building are risky and could expose to failure and require thorough structural renovation and robusting.

c) Severe, i.e. 40 to 60% of the structural elements in the building are, to some extent, risky and could expose to failure and require thorough structural renovation and robusting.

d) Moderate, i.e. 40 to 60% of the structural elements in the building are deteriorated and could expose to failure and require structural renovation and robusting.

e) Minor, i.e. 10 to 40% of the structural elements in the building are deteriorated and could impair the structural integrity and require structural renovation and robusting.

f) Good condition, i.e. less than 10 of the structural elements in the building is deteriorated and could impair the structural integrity and require structural renovation.

METHOD STATEMENT FOR CONCRETE CORE SAMPLING AND TESTING TEST METHOD

BSEN 12504-1:2009 "Testing in Concrete Structure; Cored Specimen-Taking, Examining and Testing in Compression."

SIZE, NUMBER OF CORES, AND LOCATION

DRILLING OF CORES

Core drilling is carried out by an experienced operator using water-cooled, diamond-impregnated coring barrels driven by electric equipment. Care was taken during coring using a cover meter to avoid, as much as possible, cutting off steel bars.The ring is usually bolted firmly to the concrete and care is taken over the coring rate to ensure a parallel core sample is cut perpendicular to the surface.

Cores of 100 mm nominal diameters were tested, provided that the aggregate size does not exceed 20 mm. 100 mm core was used to reduce the possibility that the core will contain steel and to restrict the sampling to a length of less than 150 mm.

The sample was severed by inserting and tapping a cold chisel down the annulus cut by the barrel to cause a break-off at the bottom of the drilled length.

Once the samples were cut, they were marked with a reference number, orientation mark, and location from within the structure and wrapped in polythene.

VISUAL EXAMINATION AND MEASUREMENT

Cores were visually examined to identify any abnormalities, presence of voids, honeycombing, compaction, cracks and segregation, coarse aggregate type, and particle shape.

The diameter was measured to within ± 1% from pairs of measurements taken at right angles, at the half and quarter points of the core.

Core length, the maximum and minimum lengths measured to ± 1% as received, and the length after completion of the end preparation.

CORE PREPARATION AND CORE CONDITIONING

The high-speed grinding using diamond-faced was the means used for end preparation of test cores. The preferred length diameter /ratio are:a. 2.0 If the strength result is to be compared to cylinder strength.

b. 1.0 If the strength result is to be compared to cube strength.

The cores were exposed to a laboratory atmosphere for three days before testing.

CORE TESTING

The compressive strength is obtained by dividing the maximum load by the average cross-sectional area and expressing the result to the nearest 0.1 MPa.

METHOD STATEMENT FOR MEASURING DEPTH OF CARBONATION

AIM AND SCOPEThe method of testing consists of determining the depth of the carbonated layer on or from the surface of hardened concrete using an indicator. This method can be carried out; on specimens taken from completed structures (site specimens) and be used for testing on-site.

Carbonation affects various properties of hardened concrete. Primarily, the protection of the reinforcing steel against corrosion, which is originally guaranteed by the highly alkaline pore solution of the cement paste, becomes lost.

A change in color shows the difference in alkalinity between carbonated and uncarbonated concrete. In contrast, the carbonation of concrete occurs when the PH of the concrete (normally 11 or 12) drops to a range between 9 and 10, according to BRE Information Paper No. IP6, 1981. This test will be carried out as per BS 1881-201:1986

PRINCIPAL APPLICATIONS

Knowledge of the depth of carbonation combined with the age of the concrete may be useful when assessing potential durability and the likelihood of corrosion of reinforcement. This test may also be useful in conjunction with some of the near-to-surface test methods to ensure that the depth of carbonation is insufficient to influence results.

PROCEDURE

- On the freshly extracted concrete core, clear the

surface immediately of dust and lose particles using a clean cloth.

- Apply phenolphthalein, a chemical indicator, by wiping

using a clean paintbrush or by spraying immediately.

- Evaluate if carbonated or uncarbonated by a change in color

- Observe measurements from the side surfaces or the broken surface.

- If weak coloration or none appears on the surface, then repeat the spray test after the surface has dried.

- Phenolphthalein indicator appears pink in contact with alkaline concrete with pH values above 9 and colorless at lower levels of pH.

ULTRASONIC PULSE VELOCITY MEASUREMENT

Advantages

The principal advantages of ultrasonic pulse velocity measurement are that it is non-destructive, quick to use, and reflects the properties of the interior of a body of concrete.

Principal Applications

The principal applications are as follows:

a) Determine concrete uniformity

b) Detect cracks and honeycombs

c) Assess concrete deterioration using a general comparative survey to locate suspected areas.

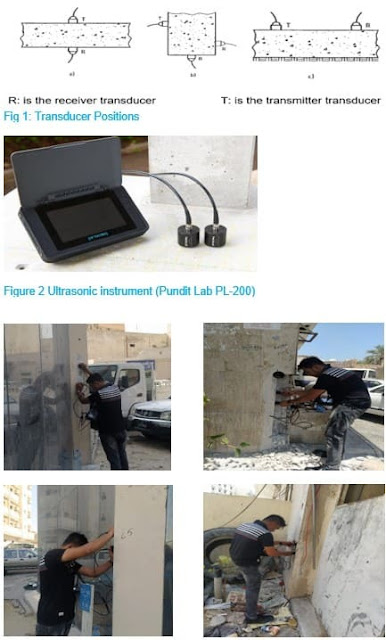

Transducers Arrangement

There are three basic ways in which the transducers may be arranged, as shown in figure1. These are

a. Opposite Face (Direct Transmission)

b. Adjacent Faces (Semi-Direct Transmission )

c. Same Faces (Indirect Transmission)

TESTING EQUIPMENT

The apparatus consists essentially of an electronic pulse generator, a pair of transducers, an amplifier, and an electronic timing device for measuring the time interval between the onset of a pulse generated at the transmitting transducer and the onset of its arrival at the receiving transducer.

The elements of the ultrasonic instrument (Pundit Lab PL-200) are illustrated in Figure 2.

PROCEDURE

- Remove the finishing layer to expose the concrete surface.

- Mark the measurement points.

- Measure the distance between the measurement points accurately to 1% of the length, the Maximum distance of direct measurement of 15m, and the distance for indirect measurement of 0.25 to 0.50m.

- Apply coupling paste to contact surfaces of the transducers (thin coat for fine concrete surface, a thicker coat for rough surface).

- Position transducers exactly on the measurement points.

- Start taking reading by UPV instrument.

- Record the reading.

METHOD STATEMENT FOR TEST OF REINFORCEMENT STEEL REBAR

1.

PURPOSE

Effectiveness and quality

of materials used in the construction of buildings, and bridges. 2. SCOPE

2.1.BS 4449-2005:2016 specifies LIMITS for Tensile Strength, Yield Strength, Elongation, and Reduction of Area.2.2.BS EN ISO 15630-1:2010 specifies test methods applicable to reinforcing bar, wires rods, and wire for concrete.

2.3.ISO 6892-1-2016 This part of the ISO 6892-1:2016 standard specifies the method for tensile testing of metallic materials and defines mechanical properties, which can be determined at room temperature.

3. EQUIPMENT TO BE USED

- Universal Testing Machine

- Digital Balance

- Steel Ruler

- Marker

- Drying Oven

4. PROCEDURE

4.1.TENSILE TESTThe test involves straining a test piece by tensile force, generally to fracture, to determine tensile strength, yield strength, and elongation test. According to ISO 15630-1; the 2010 test procedure shall be carried out in accordance with ISO 6892-1:2016. Testing rate based on stress rate (Method B) as per ISO 6892-1:2016(CL10.4) (Table 3)

4.1.1.Calculation of Tensile Strength

For the calculation of tensile properties (ReH or Rp0,2, Rm), the nominal cross-sectional area shall be used.

4.1.2. (Using Nominal Cross Section Area Define In ANNEX D(D4)

Maximum Force(kN)/Nominal Cross-Sectional Area(mm²)x1000

4.2.YIELD STRENGTH

When the metallic material exhibits a yield phenomenon, stress corresponding to the point reached during the test at which plastic deformation occurs without any increase in the force. Testing rate based on stress rate (Method B) as per ISO 6892-1:2016(CL10.4) (Table 3)

4.2.1.Calculation of Yield Strength

For the calculation of tensile properties (ReH or Rp0,2, Rm), the nominal cross-sectional area shall be used, unless otherwise specified in the relevant product standard. ISO 15630-1:2010(CL5.3)

4.2.2.(Using Nominal Cross Section Area Define In ANNEX D(D4)

Yield Load(kN)/Nominal Cross-Sectional Area(mm²)x1000

4.3.TOTAL ELONGATION AT MAXIMUM FORCE(AGT)

For the determination of the total percentage elongation at maximum force (Agt), ISO 6892-1 shall be applied with the following modification:

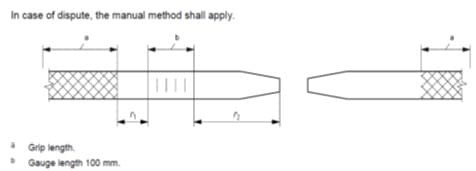

⎯if Agt is determined by the manual method after fracture, Agt shall be calculated from the following formula:

Agt =Ag +Rm / 2 000

where Ag is the percentage of non-proportional elongation at maximum force. The measurement of Ag shall be made on the longer of the two broken parts of the test piece on a gauge length of 100 mm, as close as possible to the fracture but at a distance, r2, of at least 50 mm or 2d (whichever is the greater) away from the fracture. This measurement may be considered invalid if the distance, r1, between the grips and the gauge length is less than 20 mm or d (whichever is greater).

4.4.MARKING THE SPECIMEN FOR PERCENTAGE TOTAL ELONGATION AT MAXIMUM FORCE

If the total percentage elongation at maximum force (Agt) is determined by the manual method, equidistant marks shall be made on the free length of the test piece (see ISO 6892-1). The distance between the marks shall be 20 mm, 10 mm, or 5 mm, depending on the test piece diameter.

If the total percentage elongation at maximum force (Agt) is determined by the manual method, equidistant marks shall be made on the free length of the test piece (see ISO 6892-1).

To

expedite the completion of the scope, the ------------ quarter was divided into four

(4) areas, as shown in figure ---, and eight (8) teams were deployed to extract

cores and do the field exploration and tests. Table 1 provided in this report

display numbering of the buildings as per Figure 1 and the related reference

report of each building. Also, it presents the general condition of the

building.

Compressive

strength tests were carried out according to EN 12504-1:2009, and the saturated

surface dry densities of the tested cores were determined before crush. The

results of the physical and mechanical properties of the cores are presented in

the buildings'

reports. For buildings with extracted cores less than 15, the compressive

strength is taken as the average of compressive strengths, while the building

with equal or more than 15 cores, a standard deviation was applied.

Sampling location depends on the purpose of the testing, and cores were

taken at points away from joints or edges of the concrete element and where

there is little or no reinforcement. In columns, they were taken from the

middle third of the height, and in beams, they were taken at mid-span in the

middle third of the beam depth.

The

compression test was carried out following BS EN 12390-3 using a compression

machine conforming to BS EN 12390-4.

التصنيف :

structural